One of the key specifications to consider is the material used in the construction of the replacement parts.

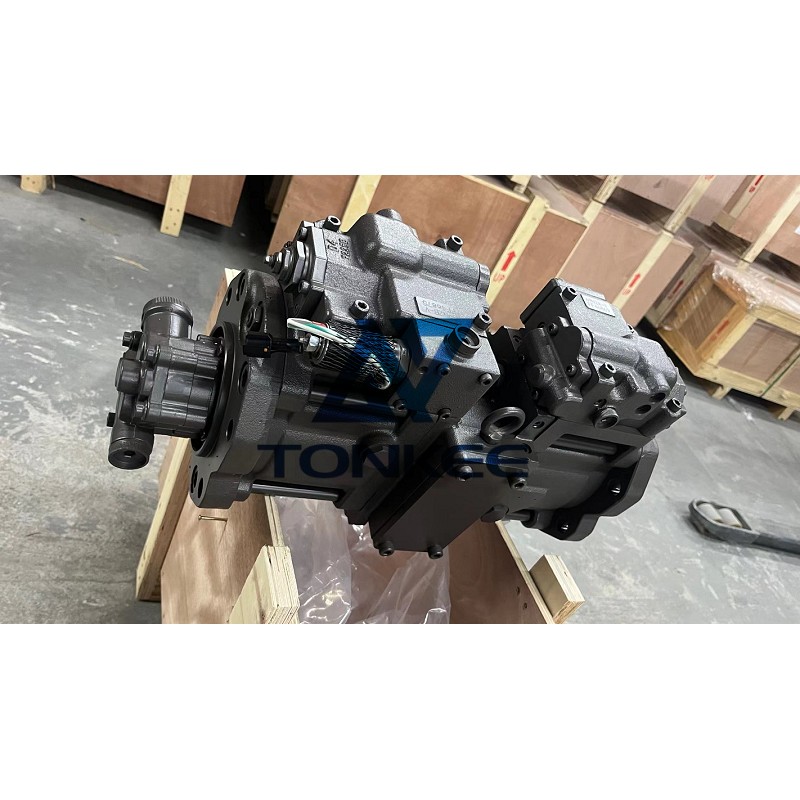

The K3V63DTP-9N2B pump is typically constructed using high-quality materials such as cast iron, stainless steel, and aluminum alloy. When sourcing replacement parts, it is important to ensure that they are made from the same materials or equivalent materials that possess similar strength, corrosion resistance, and overall durability.

Another important specification to consider is the size and dimensions of the replacement parts. The K3V63DTP-9N2B pump consists of various components such as pistons, cylinders, valves, and seals. Each of these components has specific size requirements to fit and operate properly within the pump assembly. Therefore, it is crucial to source replacement parts that match the exact dimensions and specifications specified by the manufacturer to ensure a proper fit and seamless integration.

The hydraulic performance specifications of the replacement parts are also critical. The K3V63DTP-9N2B pump is designed to provide specific flow rates, pressure levels, and efficiency. When selecting replacement parts, it is vital to ensure that they can deliver the same hydraulic performance characteristics as the original components. This includes considerations such as volumetric efficiency, maximum pressure ratings, and flow capacity. It is recommended to consult the manufacturer's documentation or work with a trusted supplier to obtain replacement parts that meet the required hydraulic performance specifications.

Sealing and gasket specifications are another important aspect when it comes to replacement parts for the K3V63DTP-9N2B pump.

Proper sealing is crucial to prevent leaks and ensure the efficient operation of the hydraulic system. The replacement parts should include high-quality seals, gaskets, and O-rings that are compatible with the specific fluids, pressures, and temperatures encountered in the hydraulic system. It is essential to choose replacement parts that are made from suitable materials and designed to provide effective sealing under the operating conditions of the pump.

Lastly, compatibility with the overall system and ease of installation are important considerations. Replacement parts should be designed to fit seamlessly within the existing pump assembly and be compatible with the surrounding components. It is beneficial to choose parts that come with clear installation instructions or support from the manufacturer or supplier.

English

English português

português Русский язык

Русский язык