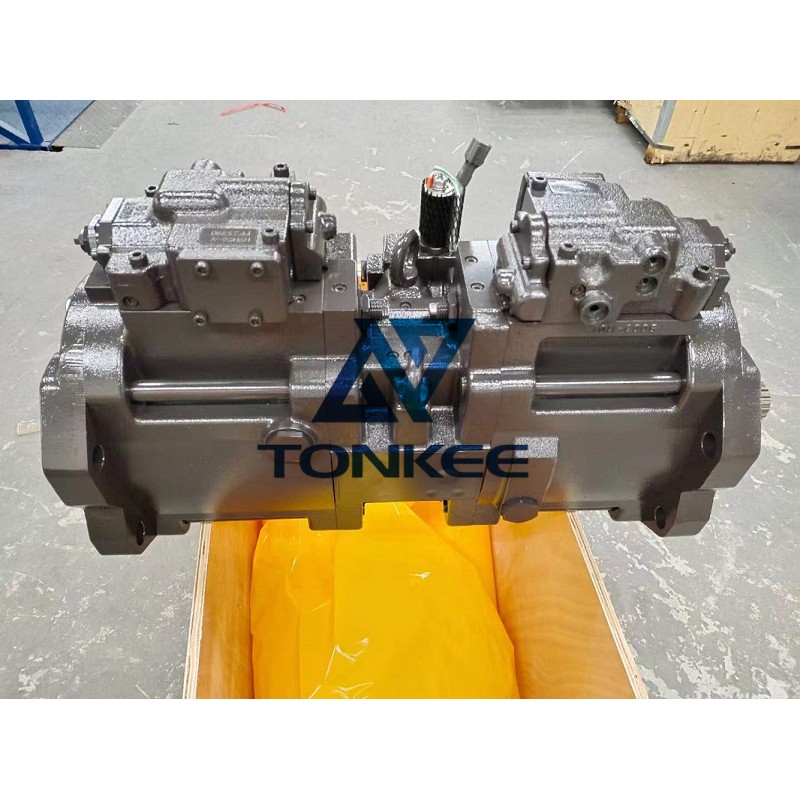

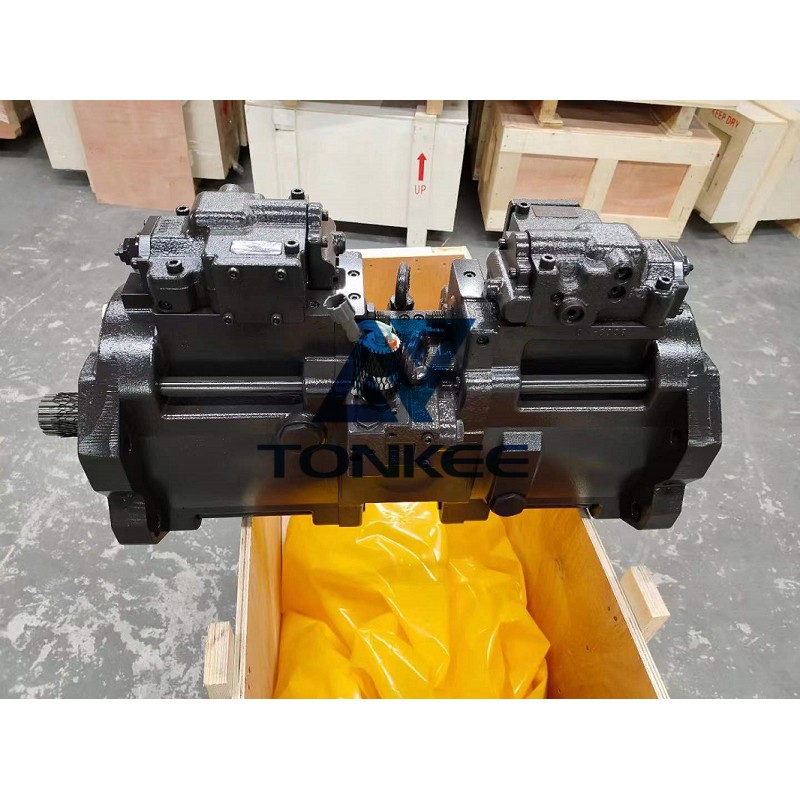

The K3V180DT-9N56 pump is known for its high-pressure capabilities, making it suitable for heavy-duty machinery and equipment.

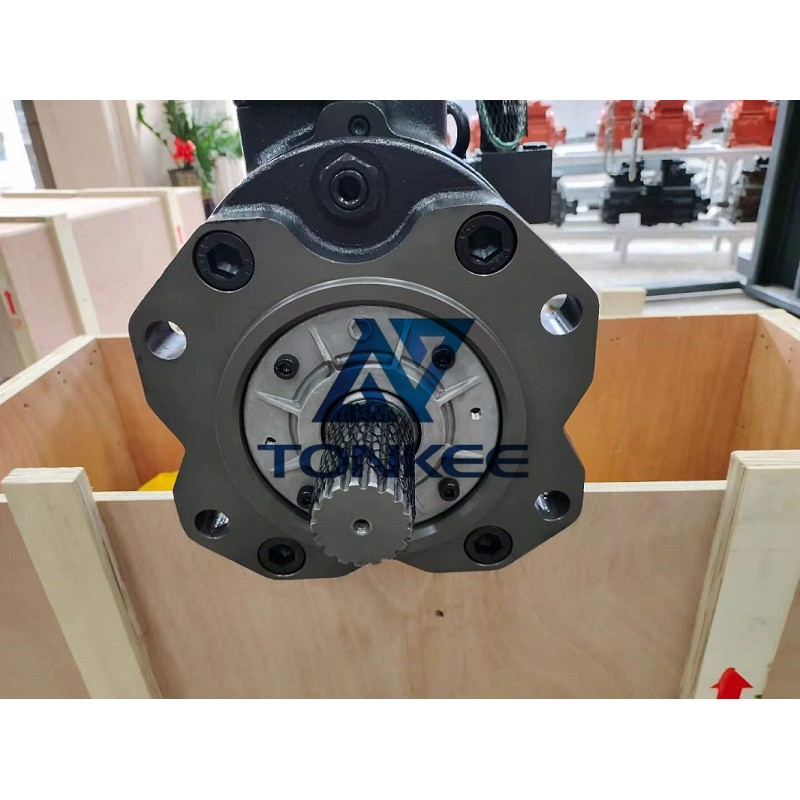

It operates based on axial piston principles, where the pumping action is achieved through the movement of pistons parallel to the drive shaft. This design ensures smooth and consistent fluid flow, allowing for precise control and operation.

One of the notable features of the K3V180DT-9N56 hydraulic pump is its compact size and lightweight construction. This makes it easier to integrate into different types of hydraulic systems, saving valuable space and reducing overall weight. Despite its compact size, this pump delivers exceptional power and performance, making it an ideal choice for applications where space is limited.

The K3V180DT-9N56 pump offers a wide range of flow rates and pressure options, providing flexibility to meet diverse system requirements. It can deliver a maximum flow rate of up to X liters per minute and can handle pressures of up to X bar. This versatility makes it suitable for various industries, including construction, mining, agriculture, and material handling.

To ensure durability and longevity, the K3V180DT-9N56 hydraulic pump is constructed with high-quality materials and undergoes rigorous testing procedures. It is designed to withstand harsh operating conditions, including high temperatures, heavy loads, and contaminants. This ensures reliable performance even in demanding environments, reducing downtime and maintenance costs.

The pump features advanced technologies to enhance its efficiency and energy-saving capabilities.

It incorporates a precise control mechanism that optimizes the flow and pressure delivery, minimizing energy consumption without compromising performance. This not only helps reduce operational costs but also contributes to environmental sustainability.

Maintenance of the K3V180DT-9N56 hydraulic pump is relatively straightforward. It is recommended to follow the manufacturer's guidelines for routine inspections, lubrication, and replacement of wear parts. Regular maintenance ensures optimal performance and extends the pump's lifespan, reducing the risk of unexpected failures and costly repairs.

English

English português

português Русский язык

Русский язык