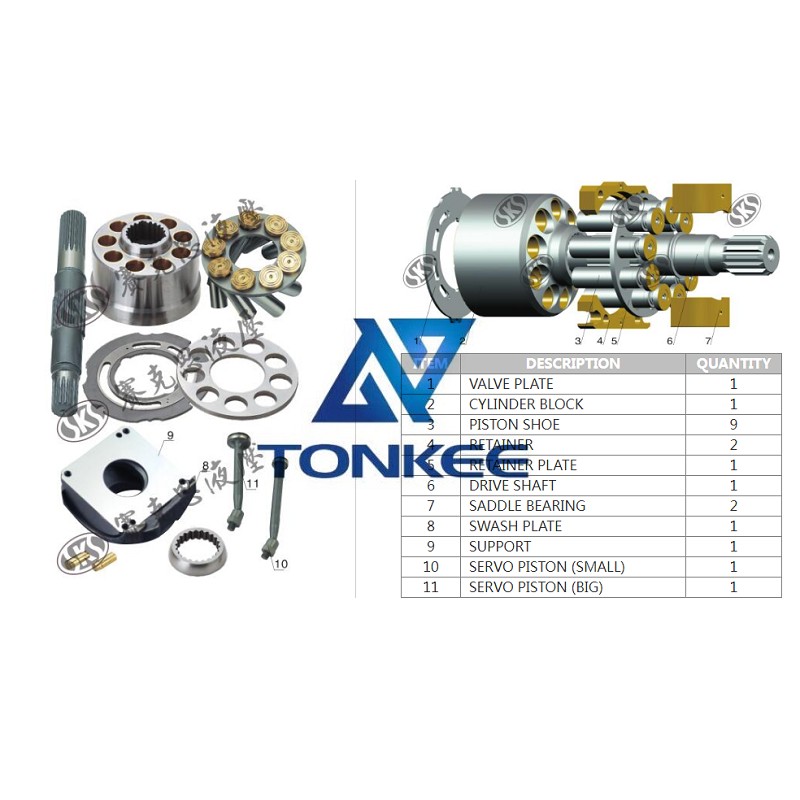

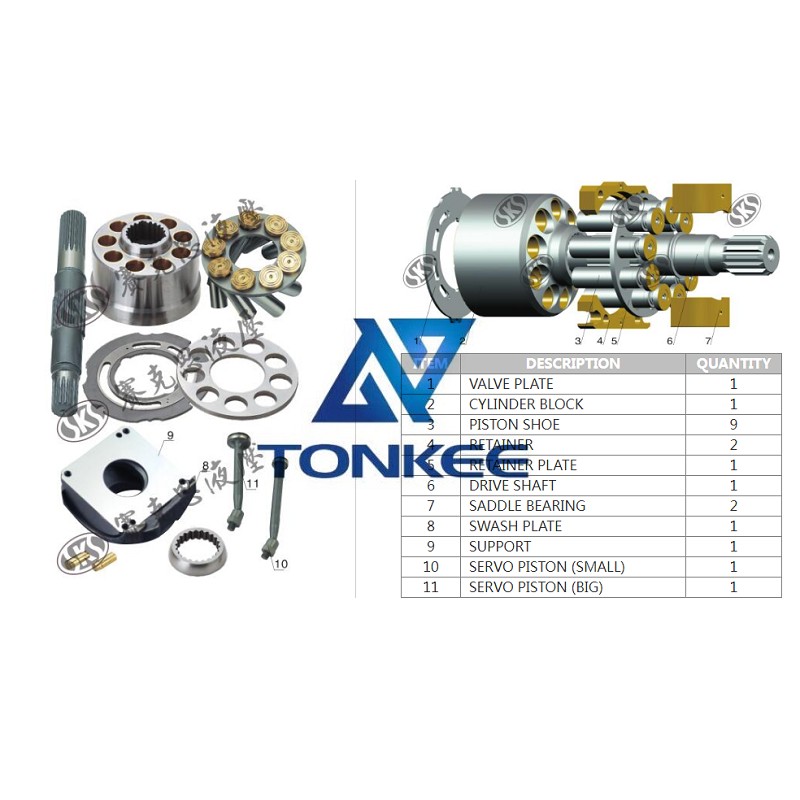

The HPR105 Retainer Plate is constructed using high-quality materials to ensure durability and resistance to the demanding conditions typically encountered in hydraulic systems.

The plate is designed to withstand high pressures and forces, offering robust support to the hydraulic pump.

One of the primary functions of the HPR105 Retainer Plate is to secure the hydraulic pump in place. It provides a sturdy mounting surface, allowing for proper alignment and positioning of the pump within the hydraulic system. This ensures that the pump remains securely fastened and prevents any unnecessary movement or vibration that could lead to damage or inefficiency.

The retainer plate also acts as a protective barrier, shielding the hydraulic pump from external elements and potential contaminants. It helps to prevent debris, dust, and moisture from entering the pump, thus reducing the risk of premature wear or damage to internal components. By maintaining a clean and controlled environment for the pump, the retainer plate contributes to the longevity and reliability of the hydraulic system.

Furthermore, the HPR105 Retainer Plate facilitates the proper distribution of forces and vibrations within the hydraulic pump assembly. It helps to evenly distribute the hydraulic pressure generated by the pump, minimizing stress concentration on specific areas. This balanced distribution of forces enhances the overall performance of the hydraulic system, promoting smoother operation and reducing the likelihood of component failure.

The design of the HPR105 Retainer Plate takes into account the specific requirements of hydraulic pumps, ensuring compatibility and ease of installation.

The plate features precise dimensions and mounting holes that align with the corresponding points on the pump and the hydraulic system. This allows for a straightforward and efficient installation process, reducing downtime and optimizing productivity.

Tonkee® maintains strict quality control measures during the manufacturing of the HPR105 Retainer Plate. Each plate undergoes rigorous testing and inspection to ensure compliance with industry standards and specifications. This commitment to quality guarantees that the retainer plate meets the necessary performance criteria, providing customers with a reliable and durable product.

English

English português

português Русский язык

Русский язык